The oil spill contingency plan for the Valdez Marine Terminal is undergoing its five year renewal. During a public comment period in December, the Council voiced concern over a “prevention credit” that reduces the amount of oil that the industry must be ready to clean up if a spill were to occur.

One of the Council’s primary duties is reviewing spill contingency plans for the oil industry in Prince William Sound. The Council has been reviewing these plans since 1990.

“Over 30 volunteers, staff, and contractors spent hours reviewing documents and coordinating these comments,” noted Linda Swiss, the Council’s project manager for contingency planning. The three volumes that make up the oil spill contingency plan for the Valdez Marine Terminal contain over 1,000 pages in total.

What’s in a contingency plan?

Oil spill contingency plans contain details about the steps to be taken before, during, and after an oil spill.

- Before: what’s being done to prevent an oil spill

- During: how the industry will respond to an oil spill, including where the equipment and personnel would come from

- After: plans are updated to reflect lessons learned from previous spills

“These plans are a good way for stakeholders to understand how their resources and livelihoods are protected,” Swiss says.

Oil spill contingency plans are prepared by the operators of Alyeska’s marine terminal and oil tankers and are subject to state approval.

There are separate plans for spills from the Valdez Marine Terminal and from the tankers that load crude oil at the terminal. Plans undergo an update, review, and approval process approximately every five years.

Liners under crude oil storage tanks still of concern

One of the central issues the Council is concerned about is an asphalt liner surrounding the large oil storage tanks.

Each tank holds approximately 23 million gallons of oil. If a tank were to leak oil, the liners act as a backup system that is supposed to contain the oil until it can be cleaned up and before it can contaminate ground water or Port Valdez. The backup or “secondary containment” system consists of a huge bowl-shaped area around the tank. The area is lined with asphalt, which is buried under several feet of gravel.

Why does the Council care about this liner?

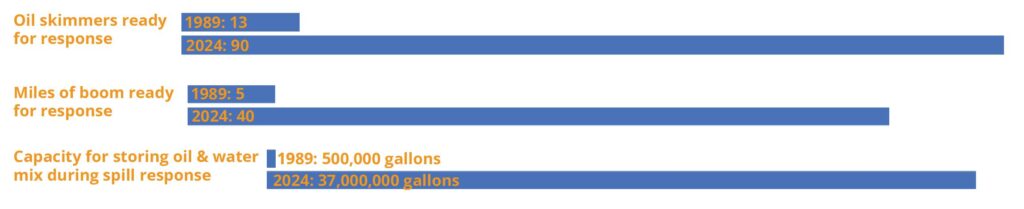

The Exxon Valdez oil spill taught the lesson that a certain amount of equipment and trained personnel must be on hand to respond quickly.

The amount of response equipment and personnel varies according to the storage capacity. At the terminal, this is based on the maximum amount one of the oil storage tanks can hold, which is approximately 23 million gallons.

Alyeska receives a 60% “prevention credit” for various prevention measures. Most of that 60% is for having the asphalt liner around the tanks. This means they plan for a spill of 40% of the total volume of one tank, which is 8.5 million gallons. If more than 8.5 million gallons is spilled, they would still be responsible for cleaning it up, however, more equipment would be needed than is currently listed in the plan.

Is the liner still intact?

This liner was installed when the terminal was built and is approaching 50 years old. From time to time, sections of the gravel layer over the liner have been removed when work is done for other projects. When this is done, cracks and holes are often found in the liner.

“There are crude oil storage tanks holding half a million barrels of oil sitting on a steep slope above Port Valdez within a secondary containment system with known integrity issues,” the Council noted in their comments.

Testing the liner

Because the liner is buried under gravel, it is expensive and time-consuming to dig it up for a visual examination. Excavation could also damage the liner. In 2022, the Council conducted a study of methods to evaluate the liner without removing the gravel. Alyeska is planning to conduct a pilot test this summer using an approach similar to the method recommended in that report.

What is a prevention credit? Spilled oil can never be completely recovered, so regulations are designed to encourage companies to prevent spills from happening in the first place. One way to do this is to give “credit” for prioritizing spill prevention.

In Alaska, the amount of equipment and personnel that an oil company must keep on hand to respond to a spill depends on the potential size of a spill. If a company takes actions to prevent or reduce the risks of a spill, they can qualify for such a credit. This allows the company to keep less equipment and personnel on hand to respond, because a spill is less likely.

Additional issues

The Council noted several issues aside from the liner, including:

- The length of time between internal inspections of the storage tanks.

- A lack of detail about the training to prevent oil spills.

- Documents containing plan information that were not made available as part of the public review.

More information

The Council’s comments: PWSRCAC comments on 2024 VMT Contingency Plan Renewal