A new Council report shows how electricity can be used to “see” damage in the asphalt liners that are intended to contain oil in case of a spill at the Valdez Marine Terminal.

The terminal’s vast crude oil storage tanks are surrounded by a secondary containment system. This system consists of huge containment cells (two tanks per cell) that would act like a bathtub, holding the oil until it can be cleaned up.

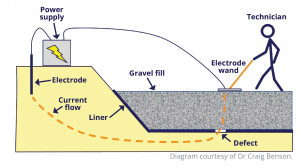

To keep oil from leaking into the surrounding environment, these cells are lined with a special type of asphalt. About 5 feet of gravel fill sits on top of this liner.

These asphalt liners can become brittle with age and are susceptible to physical and chemical damage. Over the years, the gravel fill has been removed in a few places to visually inspect the liner. About 20% of the time, holes or cracks were found.

Removing all the fill to visually inspect and repair the liner would be an expensive and time-consuming project, and the excavation equipment could cause further damage to the liner. Alyeska is looking for ways to evaluate the liner without having to excavate.

To help identify the best liner testing methods, the Council has been working with Dr. Craig H. Benson, who has been teaching and practicing environmental and civil engineering for over 40 years, and has extensive experience in containment systems. A new report by Dr. Benson has several recommendations to help the Council provide advice to Alyeska regarding the secondary containment systems at the terminal in Valdez.

Dr. Benson evaluated several liner inspection techniques and determined that electrical leak location would likely be the best. This type of survey is done by applying electric currents to the ground outside the liner and measuring electric currents on the surface of the fill inside the liner. A solid liner would block the currents. Holes or cracks would allow the current to flow through. Currents that flow through the liner can be detected from the surface, allowing technicians to create a map of damaged areas.

Dr. Benson evaluated several liner inspection techniques and determined that electrical leak location would likely be the best. This type of survey is done by applying electric currents to the ground outside the liner and measuring electric currents on the surface of the fill inside the liner. A solid liner would block the currents. Holes or cracks would allow the current to flow through. Currents that flow through the liner can be detected from the surface, allowing technicians to create a map of damaged areas.

Dr. Benson also analyzed how much of the liner would need to be tested to have confidence that the liner will reliably hold spilled oil. He determined that testing at least 20% of the liner would be enough to estimate how many holes may exist in the liner, with acceptable accuracy. However, 100% of the liner would need to be tested to find all the actual damage.

The importance of an undamaged liner

The Alaska Department of Environmental Conservation, or ADEC, gives Alyeska a 60% “prevention credit” because this secondary containment system is in place. This means that instead of having to provide response equipment to clean up a spill equal to the contents of the largest tank at the terminal (over 23 million gallons), Alyeska only has to provide response equipment and personnel to clean up a little over 8.5 million gallons.*

This is a substantial reduction in the amount of response personnel and equipment.

In May 2022, ADEC notified Alyeska that they needed to identify preliminary methods to evaluate the integrity of the liners by October 2023. Alyeska must identify final methods to evaluate these liners by March 2025.

Dr. Benson’s report is available online: Methodologies for Evaluating Defects in the Catalytically Blown Asphalt Liner in the Secondary Containment System at the Valdez Marine Terminal

*8.5 million gallons, or 204,180 barrels, is the volume of the largest tank, less a 5% prevention credit for drug/alcohol testing, 2% prevention credit for on-line leak detection, and 60% prevention credit for the secondary containment system.