How do you detect damage underground? The Council, Alyeska, and the Alaska Department of Environmental Conservation, or ADEC, have been trying to answer that question. The results from a recent pilot test are providing direction to help ensure that oil will not leak through the secondary containment liners under the storage tanks at the Valdez Marine Terminal.

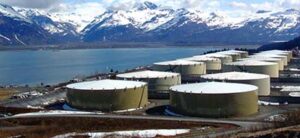

How do you detect damage underground? The Council, Alyeska, and the Alaska Department of Environmental Conservation, or ADEC, have been trying to answer that question. The results from a recent pilot test are providing direction to help ensure that oil will not leak through the secondary containment liners under the storage tanks at the Valdez Marine Terminal.

Finding flaws in an underground liner

Last summer, Alyeska conducted a pilot test for locating damage in the special asphalt liners that surround the crude oil storage tanks at the terminal.

The liners are part of a system surrounding the tanks that is designed to prevent oil from leaking into the environment. The liners are difficult to examine because they are buried under several feet of earthen fill. Digging them up for inspection is expensive, time-consuming, and historically has caused damage.

Since the liners were installed nearly 50 years ago, only a small percentage has ever been uncovered and evaluated for damage. When sections have been uncovered, holes or cracks have been found about 19% of the time.

Both Alyeska and the Council have been looking for a method that can determine whether there are cracks or faults in the liner, and if so, where they are located, without having to dig, per requirements set by ADEC.

Results from pilot test

Of the methods that were tested last July, electrical leak location was determined to be the most feasible. This type of survey is done by applying electric currents to the ground outside the liner and measuring electric currents on the surface of the fill inside the liner. A solid liner would block the currents. Holes or cracks would allow the current to flow through. The currents that flow through the liner can be detected from the surface, allowing technicians to create a map of damaged areas.

Further analysis to come

Alyeska conducted this pilot test in preparation for a larger-scale test. When approving the last update to Alyeska’s oil spill contingency plan, ADEC placed a condition on the plan’s approval, requiring that Alyeska conduct further analysis of the liner. The timeline for these additional tests is yet to be determined.

How much of the liner needs to be tested?

The Council hired Dr. Craig Benson, Distinguished Professor Emeritus of the University of Wisconsin-Madison, and Dr. Joe Scalia, Associate Professor of Civil and Environmental Engineering at Colorado State University, to weigh in on the pilot test results. They determined that when the large-scale testing is done, at least 20% of the liner needs to be examined to be able to confidently estimate the frequency and size range of defects in the liner.

Details in the report:

Find out more about the pilot test and the expert’s recommendations in the report: Review of Pilot Study of Secondary Containment System